Home

Here at Rapid Plating we provide a number of different metal finishing processes. We are located in the

St. Cloud/ Sauk Rapids area servicing Central Minnesota. We are Minnesota's Finest chrome plating and metal finishing shop.

Rapid Plating has specialized in metal finishing for 29 years in the Central Minnesota Area and when it comes to plating we are 2nd to none! You truly do get what you pay for when it comes to metal finishing.

All of them are done in house. We also provide heat-treating of small parts.

Services

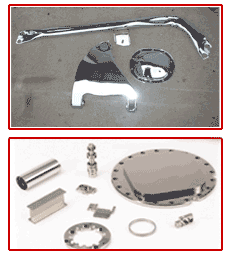

Chrome Decorative chrome can be applied to many different

Decorative chrome can be applied to many differentmetals. This process includes a base plating of nickel,

copper if needed, then chrome is applied over the top.

Size limit of parts is (67”L) x (40”H) x (15”Wide)

Nickel

There is a nickel finish for almost any need.

This coating is widely used in the tool industry

Some of the Current Applications Include:

Machining, Tooling, and Decorative Applications

Exhaust Pcs, Stoves, and High Wear Parts

Size limit of parts is (67”L) x (40”H) x (15”Wide)

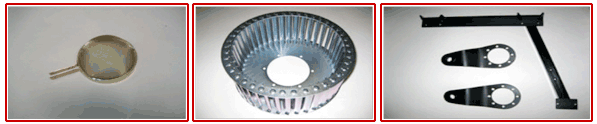

Black Oxide

Great for shafts, tight clearances, collars, machined

parts, threads, and more. There is no "plating" thickness

so all finished parts can be accurately re-assembled and

used with no re-tapping or threading

Size Limit of Parts is (35"L) x (35"W) x (32"H)

Zinc

This is by far the most widely used coating on the market

today. Bright zinc coatings closely resemble bright chromium.

The only difference is durability. Weathering, scratches, humidity,

nothing is too extreme for zinc.

Size limit of parts is (67”L) x (40”H) x (15”Wide)

We offer Zinc plating in 3 Distinct Colors:

YellowClearBlack

E. N. (Electroless Nickel)

E. N. (Electroless Nickel)This plating process is very accurate and un-matched

in its uniformity. Due to its non-electricity based

chemistry, it out performs reg. nickel in almost all ways.

This process is unique because anywhere that

liquid can get to, is evenly plated.

Size Limit of Parts= (38"W) x (38"L) x (32"H)

E. P. (Electropolishing)

EP provides a uniform even surface that is bacteria

and contamination resistant. The electropolish process is

is the removal of material to form a highly reflective

surface; taking off burrs, scratches, and sharp edges.

Electropolishing is most frequently used on stainless

steel. Finishes vary from satin to mirror depending on

base Size Limit of Parts= (38"L) x (38"H) x (10"W)